ISO 13485 factory for Adult Diapers With Tabs. CE-ready files, skin-safe materials, UDI/labels, OEM/ODM customize support. Get a checklist and start today.

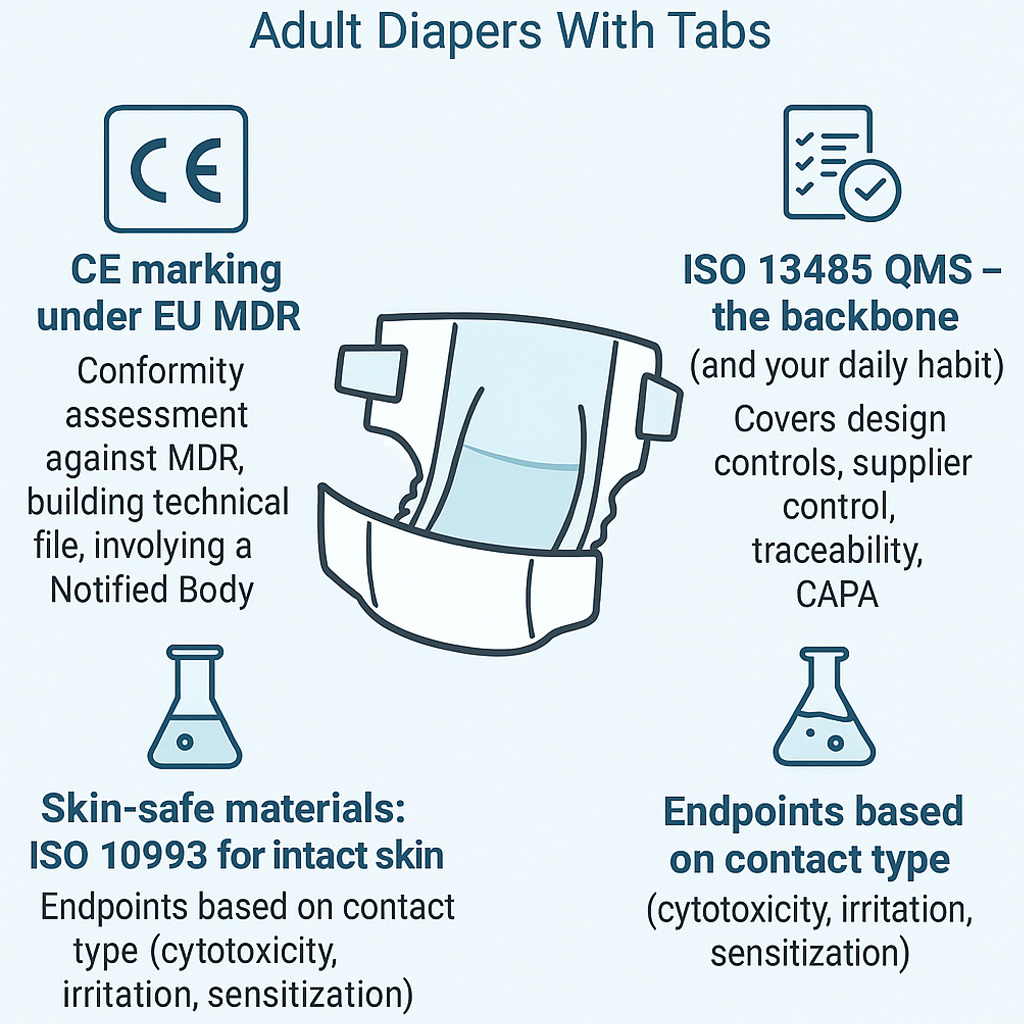

If your product touches skin, compliance isn’t paperwork — it’s your market passport. For Adult Diapers With Tabs, the rules are clear: CE under EU MDR, ISO 13485 for the quality system, and ISO 10993 for skin safety. Do these well, and the rest gets simpler, and you’ll feel it later in audits, recalls, and unhappy users.

CE marking is about conformity assessment against MDR. You classify the product, build technical documentation, and (for most classes) involve a Notified Body. After the green light, you place the CE mark.

Pain points we can see:

CE readiness quick-check

| Step | What to show reviewers | Pro tip from the line |

|---|---|---|

| Classification & route | Classification memo + rationale | Quote MDR text in-line; don’t assume. |

| Technical file | Device description, design/manufacture, GSPR table, risk files, V&V | Cross-reference everything; no orphan docs. |

| Clinical evaluation | CEP/CER summary, state-of-the-art, benefit-risk | Keep claims consistent with labeling. |

| PRRC & NB | PRRC CV/contract; NB scope match | Get NB scope confirmed early. Saves weeks. |

ISO 13485 is the daily routine that makes CE audits predictable. It covers design, purchasing, production, installation/servicing, complaint handling, and CAPA. In a diaper factory, this shows up as:

Adult diapers touch intact skin. For that contact type, the usual risk-based endpoints are cytotoxicity, irritation, and sensitization. Test plans live in your BEP (Biological Evaluation Plan).

Biocompatibility map for surface-contact (intact skin)

| Scenario (use) | Typical endpoints | What reviewers look for |

|---|---|---|

| Short wear | Cytotoxicity | Valid sample prep, controls, acceptance rationale |

| Repeated daily wear | Cytotoxicity, Irritation, Sensitization | Justification for test selection; history of safe use; chemistry if helpful |

| Extended wear (overnight, bedridden) | Cytotoxicity, Irritation, Sensitization, Chemistry/Tox assessment | Extractables/leachables logic, margins of safety narrative |

Don’t trip on sample prep. ISO 10993-12 tells you how to prepare extracts. Use proper surface area/volume ratios and relevant vehicles.

Chemistry first, sometimes. A good ISO 10993-18 chemical characterization plus tox risk assessment can reduce unnecessary biotests if your materials are well known and controlled.

Use ISO 15223-1 symbols to cut language burden. Keep claims aligned with the CER and your verification. Assign UDI (Basic UDI-DI + UDI-DI) and keep the database entries tidy before placement on market.

Mini labeling checklist

| Label element | Why it matters | Quick tip |

|---|---|---|

| Intended use & user | Drives classification and claims | Keep it one sentence, human-readable |

| Symbols | Faster comprehension, less text | Use the harmonized list; no custom icons |

| UDI | Market traceability & recalls | Print-quality checks at real line speeds |

| Storage & disposal | Safety and environment | Match to material specs and local rules |

ISO 14971 ties everything together. You identify hazards, apply controls, weigh residual risk, and then use PMS (post-market surveillance) to confirm reality matches the plan.

A simple PMS loop

| Input | Action | Record |

|---|---|---|

| Complaints, returns, trend signals | Investigate, trigger CAPA if needed | Complaint files, CAPA log |

| Clinical/market literature | Update state-of-the-art & CER | CER addendum |

| Manufacturing nonconformities | Root cause, preventive changes | NCRs, process updates (IQ/OQ/PQ) |

| Supplier changes | SCAR or re-qualification | SCAR file, supplier scorecards |

LOVINHUG is a Manufacturer with ISO 13485 support culture, not just certificates on a wall. We run factory processes with traceability, IQ/OQ/PQ, and supplier control that fit MDR logic. We also customize (OEM/ODM) briefs for private-label partners — specs, pack copy, symbols, and UDI formatting aligned to your market. You bring the brand and channel. We bring compliant design and repeatable production. Not perfect English here, but we do the work.

Use cases we serve: hospitals, nursing homes, home-care, and DTC brands across North America, Europe, MENA, SEA, LATAM, and Oceania. Certifications we’re familiar with: Adult Diaper CE paths, FSC materials chain, new cGMP expectations.

Compliance looks heavy. But with a living ISO 13485 system, a sharp BEP, and clean labeling/UDI, it becomes muscle memory. That’s how you scale Adult Diapers With Tabs without drama.

Want help or a quote? Fill out the LOVINHUG contact form and we’ll reply fast.