Odor control for Incontinence Pads: pH-smart surfaces, SAP stacks, and real adsorbents. OEM/ODM with a manufacturer who designs for skin, fit, and daily life.

Urine itself isn’t super stinky. The trouble starts when urea meets urease-positive bacteria. That reaction releases ammonia and other volatiles. When surface pH creeps up (goes more alkaline), bacteria work faster and skin gets cranky. So odor control isn’t only “more absorbent core.” It’s: keep the surface slightly acidic, block the enzyme route, and lock volatiles before they escape.

You see it after long wear, during warm weather, or when airflow is poor. Pads feel “not soaked,” yet a whiff sneaks out. That’s pH and micro-climate doing mischief.

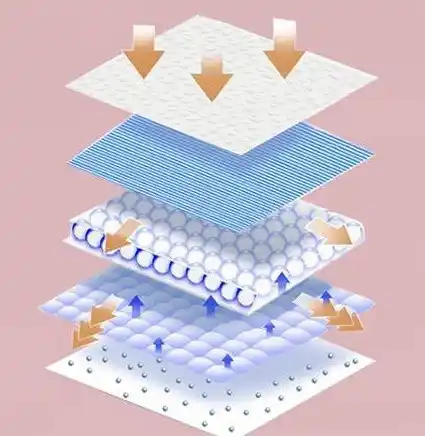

Superabsorbent polymer (SAP) pulls in liquid and locks it under load. Great. But odor control needs more than grams of SAP. You want a balanced core stack:

Lovinhug focuses on that system view—not only SAP load. If you’re sourcing OEM/ODM from a manufacturer like us, ask for topsheet pH spec range, rewet under pressure, and odor panel notes, not only “absorbency ml.”

Fragrance masks, but you want capture. Three workhorses:

| System | What it targets | Where it sits | Pros | Watch-outs | Use cases |

|---|---|---|---|---|---|

| Activated carbon | Phenolics (like p-cresol), a range of VOCs | In core or laminated patch | Broad spectrum, proven | Can load with moisture; needs airflow balance | Overnight pads, disposal bin inserts |

| Zeolite (clinoptilolite etc.) | Small/polar molecules including ammonia | Core blend or coating | Selective, heat-stable | Powder handling; choose pore size wisely | Day pads, warmer climates |

| Zinc ricinoleate | Amines/sulfurous compounds | Coating/dispersion in nonwoven | Chemical complexation, long-lasting | Needs proper dispersion to avoid spots | Premium lines, “no-perfume” briefs |

None of these replace pH control. Think layered defense: pH-friendly surface → fast move → lock → adsorb gases. That stack wins.

You can smell a pad that “burped” a little moisture back to the topsheet. Rewet pushes volatiles to air. Controls:

Go with Daily Invisible Women’s Incontinence Liners. Thin feel, fast wicking.

Tip: swap before long meetings; pH drift is sneaky.

Men’s Incontinence Guards line up with the flow path and seal edges better.

Tip: press the adhesive from base to tip; don’t leave the nose floating.

High Capacity Women’s Heavy Flow Pads offer more lock-in without going to a brief.

Tip: don’t overspec; bulk can warm the micro-climate.

Add a Adult Diaper Booster Pads layer. Flow-through logic lets the base pad keep doing the heavy lift.

Tip: don’t stack too many; airflow matters for odor, too.

These are small, but they stack up—less odor, calmer skin.

LOVINHUG is a manufacturer with ISO 13485 culture, serving distributors, hospitals, nursing homes, retailers, and DTC brands across North America, Europe, MENA, SEA, LATAM, and Oceania. Our OEM/ODM teams don’t chase a single headline metric. We design for system performance:

| Situation | Priority | Core choice | Add-ons | Fit notes |

|---|---|---|---|---|

| Light, discreet, office hours | Low rewet, stealth | Thin SAP with smart surge | None or micro zeolite | Centered placement, smooth edges |

| Male stress, active day | Edge seal, cup shape | Guard geometry + fast wicking | Optional carbon patch | Press adhesive from base to tip |

| Afternoon long sit | pH stability | Buffered core + acidic topsheet | Zeolite blend | Don’t over-compress waistband |

| Night sleep, warm room | Gas capture | Higher capacity core | Carbon or zinc ricinoleate in pad, bin filter | Fresh pad before bed |

Hold the pH line, move fluid fast, lock it down, and catch the gases. Nail fit so volatiles don’t sneak out the edges. Use routines that respect skin and time. When you need a partner, pick a manufacturer that gets both the science and the day-to-day. Lovinhug does OEM/ODM with that exact mindset—practical, testable, humane.

Questions or custom brief?

Please fill out the contact form on lovinhug, we’d love to help.