Protect ABDL prints with smart tape choices. Balance peel/shear, pick the right landing zone, and test for clean re-tapes. OEM/ODM with Lovinhug.

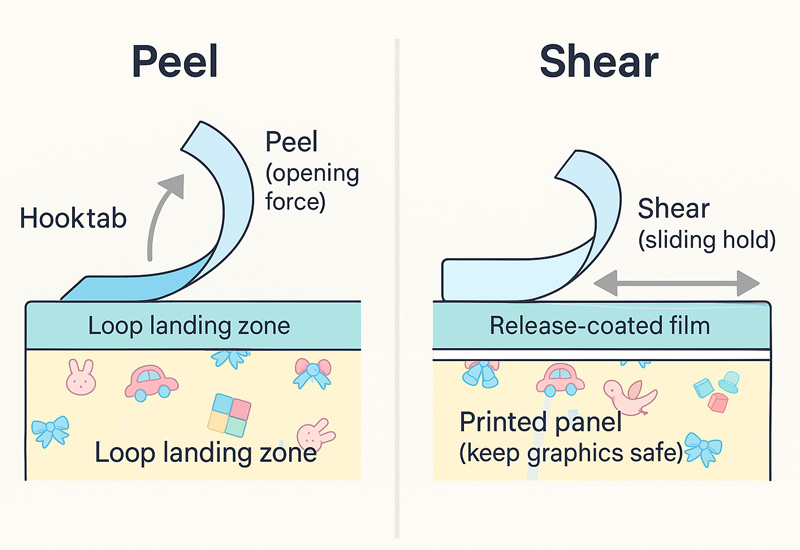

“Hold” isn’t just one thing. It splits in two:

You want high shear (so it doesn’t creep or sag) and moderate peel (so you can reopen without yanking ink). Hit that balance and you keep the print fresh. Miss it and you get silvering, whitening, or even film lift.

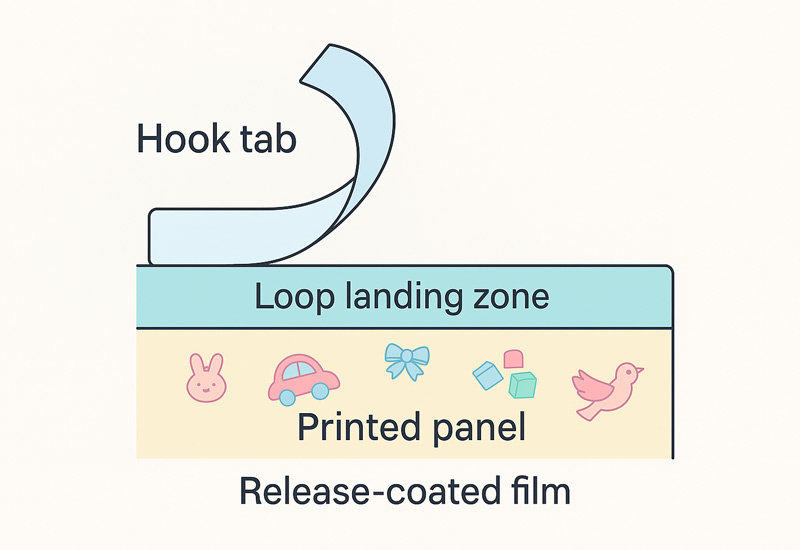

Hook tabs into a loop panel are naturally re-close friendly. The loop fabric is the sacrificial layer, not your printed film. If you run ABDL designs with glossy graphics, this setup is forgiving. It also plays nice with wetness indicators because you can land the tabs on the loop, not the printed area.

Adhesive works great too—if you pair it with a release-coated frontal film (often silicone-coated BOPP). The coating lets you unstick and restick without ripping color. Don’t plant adhesive straight on raw printed film. That’s how you scuff. It do damage, fast.

| Decision point | If you choose this | What it protects | Risk if mismatched | Operator note |

|---|---|---|---|---|

| Tab type | Hook tabs | Printed film (ink sits safe behind loop) | Hook landing on smooth film → weak hold | Check hook density vs loop grade |

| Landing zone | Loop panel | Refastening cycles | Adhesive onto bare print → ink lift | Keep loop edge aligned, no overhang |

| Frontal film | Release-coated BOPP | Clean peel, lower ink stress | Uncoated film → noisy peel, scuff | Replace rolls if coating wear |

| Test focus | Shear priority | No night-time creep | Over-peel → hard to open | Tune to “high shear / moderate peel” |

| Re-tape flow | On-zone every time | Graphics, wetness marks | Off-zone → delam spots | Train: “on the zone, every time” |

| Test | What it checks | Why you care | Good outcome looks like | If it fails |

|---|---|---|---|---|

| 90° peel (closure) | Opening feel | Re-tape without shock to ink | Steady, not spiky; no film whitening | Shift to lower-tack or better frontal |

| 135° peel (closure) | Edge-case peel path | Catch worst-case angles | Smooth release; no “snap” | Change angle spec or tab cut |

| Moving shear | Long hold under load | Stops “tab creep” at night | No drift over the dwell window | Bump shear; keep peel moderate |

| Cross-hatch tape (print) | Ink adhesion on film | Predicts print lift | Grid stays put after pull | Change ink/primer/cure |

| Hand re-tape cycles | Real user abuse | Validates loop or release film | Clean multiple re-tapes | Upgrade landing surface |

The pattern is what matters: shear up, peel reasonable, ink stays.

| Symptom | Likely cause | Fast fix | Longer fix |

|---|---|---|---|

| Print scuffs on first reopen | Adhesive on raw print | Land on zone, not print | Add release-coated frontal |

| “Pop-open” after movement | Low shear | Press harder / micro-slide | Change to higher-shear spec |

| Loud peel + color ghosting | Over-tacky tab / tired film | Lower tab pressure | New frontal roll / new coating |

| Loop fuzzing out | Hook too aggressive | Shift hook density | Denser loop grade |

| Tabs drifting overnight | Poor shear / humidity | Add second press | Re-spec tab adhesive window |

A brand shipped an adhesive-tab design straight onto a printed BOPP. Open once, fine. Second open, white scuffs across the dragon graphic. Fix was simple: swap in a release-coated frontal and retrain “peel low and slow.” Scuffs gone, returns down. Graphics look new after multiple re-tapes.

You want a partner that builds with print safety in mind. Lovinhug is an ABDL Diapers manufacturer and ABDL Diapers factory with ISO 13485 mindset, CE and FDA support, and FSC materials options. We do OEM/ODM for private-label partners across North America, Europe, MENA, SEA, LATAM, and Oceania. That means:

Want to see direction examples? Browse ABDL Diapers for silhouettes and panel concepts, or look at Leak-Proof ABDL Diaper for Adult Men and Women to understand how we zone the front for clean re-tapes.

Strong tabs are great. Smart re-tapes are better. Protect the print, and the whole product feels premium longer. You can feel the difference when you open, adjust, and close. So can your customers.

Questions or ready to prototype?

Welcome to fill the Lovinhug contact form, and we’ll reply fast.